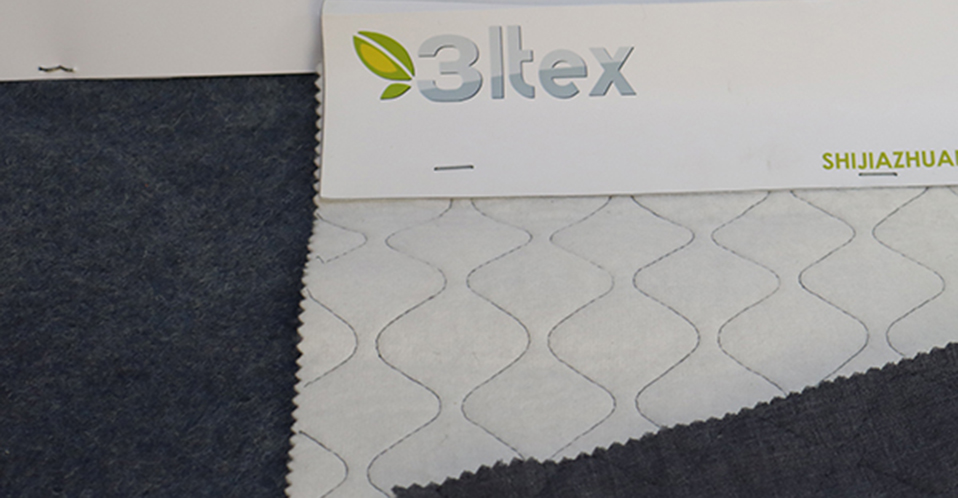

Meta aramid fiber fire insulation felt

At the same time it can be used as a filter felt.

The characteristic of this kind of fabric is not only its flame-retardant and fire-proof, but also that it can provide anti-static and anti-arc effects.

This fabric has high strength and remains unchanged after times washing because of its good abrasion resistance.

Fabric weight: 70/90/150g/m2 or customized according to customer requirements

Regular color: white

Regular structure: Spun lace or needle punched non-woven fabric

Width: 150 cm ((59" -60 ")

2-2-Fire-fighting quilted felt

Linging Fabric

50% Meta aramid +50%FR Viscose

heat insulation layer-

100% Meta aramid spunlanced Felt

Weight of lining fabric 120g/M2

Weight of insulation layer 150g/M2

Dope dyed

Width: 150 cm ((59" -60 ")

Standard: GA10-2014/GB8965.1-2009/ISO11612/ EN14116/ EN469

IIIA Fabric

Material:

Features:

√ Good & Permanent flame Retardant

√ Excellent heat-insulating

√ No molten drop

√ Don 't generate poisonous gas

√ Anti-static (with conductive fiber)

√ Acid and alkali resistant

√ High strength, wear resistance & anti-tear

√ No cracking

√ Great air and water vapor permeability

√ Resistance to laundering

Applications:

Technical Data:

|

Model No. |

Material |

Weight (g/m2) |

Color |

Dyeing |

Remarks |

|

NKD4011 |

93% Meta Aramid + 5% Para Aramid + 2% Conductive Fiber |

200g |

Orange(Grid) |

Dope dyed |

|

|

NKD4621 |

93% Meta Aramid + 5% Para Aramid + 2% Conductive Fiber |

210g |

Dark Blue |

Dope dyed |

Firefighter Uniform Outter Fabric |

|

NKD419 |

93% Meta Aramid + 5% Para Aramid + 2% Conductive Fiber |

150g |

Dark Green |

Dope dyed |

|

|

NKD428 |

93% Meta Aramid + 5% Para Aramid + 2% Conductive Fiber |

210g |

Royal Blue |

Dope dyed |

FR Uniform Outter Fabric |

|

NKD407 |

93% Meta Aramid + 5% Para Aramid + 2% Conductive Fiber |

200g |

Dark Blue(Grid) |

Dope dyed |

Firefighter Uniform Outter Fabric |

|

NKD405 |

93% Meta Aramid + 5% Para Aramid + 2% Conductive Fiber |

150g |

Orange |

After Dyed |

FR Uniform Outter Fabric |

|

NKD440 |

93% Meta Aramid + 5% Para Aramid + 2% Conductive Fiber |

210g |

Flag Red |

Dope dyed |

FR Uniform Outter Fabric |

According to standard: EN11612, EN11611, EN469:1995

Pre-oxidized Fiber & Para Aramid Blended Yarn

Polyacrylonitrile Pre-oxidized fiber referred to as the pre-oxidized fibers.

It's a new flame-resistant (non-flammable) fiber rise with the development of carbon fiber.

Material:

Main Feature of Pre-oxidized Fiber:

√ Non-combustible, insoluble, non-drip, non-softening, non-shrink in flame

√ 3mins flame-resistant in 900 ℃ flame, remains a prototype until be carbonized

√ Soft and not brittle at -100 ℃

Applications:

Technical Data:

According to standards: GA634-2006、EN(ISO)11612-2008、CS-191

Aramid Covered Steel Yarn

Core Material: 316L stainless steel wire / yarn

Covered material: Aramid 1313 or 1414 filament or short fiber yarn

Features:

- High strength

- Flame retardant,

- High temperature resistance 500℃

- Thermal insulation

- Abrasion resistance

- Outer insulated layer

Specifications:

Aramid 1414 316L stainless steel wire

200D-1000D 1-10 filaments

Aramid 1313 316L stainless steel wire

30S/1,30S/2,30S/3 1-10 filaments

Main applications:

cable, fiber optic cable tensile reinforcement, rubber products’ filling enhancement.

Protective clothing, cut-resistant gloves, high-temperature insulation sleeves, leather products, aramid webbing, etc.

used for high-temperature, wear-resistant, cut-resistant and other occasions,Such as insulation layer for boiler exhaust pipe.

Meta Aramid Yarn & Thread

Type:

Main Feature:

√ No molten drop, avoid secondary burns

√ Impressive permanent flame Retardant

√ Resistance to laundering

√ Long-lasting thermal stability

√ Excellent chemical stability

√ Excellent mechanical properties

√ Super-resistant to radioactive: 1313-resistant aramid α, β, χ-rays and ultraviolet radiation

Applications:

flight suit, anti-chemical warfare clothing, fire fighting suits and blast furnace work clothes, welding clothes, all subdued, radiation-proof overalls, chemical protective clothing, high-pressure shield clothing and other special protective clothing, for aviation, aerospace, military uniforms, fire protection, petrochemical, electrical, gas, metallurgy, racing and many other fields.

Technical Data:

10S-18.5S.20S.24S.30S.35S.40S

30S/2,30S/3,20S/3,20S/2,40S/2,40S/3,60S/3

According to standards: EN11612,EN14116,EN469,EN1149,GB8965.1-2009 NFPA-2112

Stainless steel & Aramid Blended Yarn

Material:

Main Feature:

√ Conductive

√ Fire Resistance

√ High Strength

√ Heat Resistance

Applications:

Technical Data:

|

Yarn Count |

Material |

Proportion |

Resistance (Ω/cm) |

|

20s/1 |

SSF/ Para Aramid |

50:50 |

1-1.2 |

|

20s/2 |

SSF/ Para Aramid |

50:50 |

0.6-1 |

|

30s/1 |

SSF/ Para Aramid |

27:73 |

20-40 |

Aramid Rope

Aramid filaments braided into coreless, or cored (such as stainless steel wire) ropes, high-strength, high-temperature resistant.

Features:

high temperature resistance, fire retardant, light weight, high strength, high modulus, stable size, low shrinkage, puncture resistance, cut resistance, abrasion resistance, heat resistance, chemical resistance, good mechanical properties, good dielectric properties, etc.

There are three types of square rope, flat rope and round rope.

The specific specifications are as follows:

Square rope specifications:

3X3mm 4X4mm, 5X5mm, 5.5X5.5mm, 6X6mm, 7X7mm, 10X10mm

Flat rope specifications:

12X4mm12X3.5mm 12X5.5mm 13X3.5mm 13X3mm 10X4mm 10X3mm 9X4mm 9X3mm 8X3mm

Round rope specifications: 2mm—12mm

Applications: fire ropes, high temperature straps, wear-resistant ropes, aramid engineering ropes, roller track ropes, suspension ropes, aramid safety ropes, aerial ropes, traction ropes, aramid leisure ropes, paraglider ropes, Water skiing traction ropes, aramid marine rescue ropes, transportation hoisting ropes, puncture-resistant cutting ropes, abrasion-resistant aramid ropes, fire-resistant flame-retardant ropes, high-temperature-resistant ropes, chemical-resistant aramid ropes, and other special requirements for rope .

Pre-oxidized fibers & Aramid Blended Fabric

Polyacrylonitrile Pre-oxidized fiber referred to as the pre-oxidized fibers.

It's a new flame-resistant (non-flammable) fiber rise with the development of carbon fiber.

Material:

• Preoxidation fiber 60%

• Para Aramid fiber 40%

• Width of 150cm

Features of Polyacrylonitrile Pre-oxidized Fiber:

√ Non-combustible, insoluble, non-drip, non-softening, non-shrink in flame

√ 3 mins flame-resistant in 900 ℃ flame, remains a prototype until be carbonized

√ Soft and not brittle at -100 ℃

√ Strength 1.6-2.3dn/tex

√ Limiting oxygen index of 55-60%

√ Elongation rate 12-16%

√ Initial modulus of 70-80 dn / tex.

√ Moisture absorption rate of 6% -10%

√ Thermal conductivity coefficient 0.08-0.17j / (m • s • k)

Technical Data:

• Weight of 260±5g

• After flame time: 0 seconds

• Afterglow time: 0 seconds

• Damaged length: 0mm

• Moisture absorption: 6210g/㎡•24h

• 13 Seconds' shrinkage in 800℃ flame:3.31%; 1 minute shrinkage in 800℃ flame:4.29%;Breaking strength: Warp 1100N , Weft 850N

• Tearing strength: Warp 110N , Weft 120N

Applications:

• Fire suits, thermal insulation clothing (fire, smelting, welding, arc)

• Home textiles, fire barriers (curtains, mattresses, lining)

• Fire tent

• Swat fire fighting clothing, still can survive and fight in a sea of fire

• Insulation materials used in electricity, communications

• Industrial, military equipment, facilities, fire protection jacket Fire, heat and sound insulation components in automobile industry

• Heat insulation, flame retardant material used in seats of airplane, train, automobile

According to standards: GA634-2006、EN(ISO)11612-2008、CS-191